Topic Highlights

Water is vital to human health, energy, and healthy ecosystems. Sustainable water management is critical for protecting ecosystems and building resilience in the face of climate change.

We strive to reduce water use within our operations, select water sources with adequate and sustainable capacity, and prevent impacts on our local water supply.

In 2023, we:

- Recycled 96% of our produced water;

- Continued to expand our water network throughout West Virgina; and

- Recorded no well integrity failures that resulted in a negative environmental impact.

What We are Doing

Natural gas production requires water to operate sophisticated processes and procedures. Water management is a necessary, and often critical, component of many of our core operating functions and is used to safeguard both human and ecological health. In addition, the efficient use and transport of water improves the overall efficiency of our operations. The most significant impact that water has on our success is tied to its direct effect on our ability to complete wells and produce natural gas. We work to uphold ambitious standards of water management to preserve stakeholder trust, minimize our environmental impact, and protect this valuable natural resource. We use best-in-class management practices to evaluate water sources, permit locations, operation of withdrawal sites, and discharge of water. We identify potential risks at each stage of our operations and implement appropriate mitigation measures. Further, we strive to protect the fresh water in our communities by investing in innovative technology, following industry best practices, and recycling of water whenever possible. Recycling wastewater is the most effective solution to minimize our water-related environmental impacts. We strongly support transparency and disclose the chemical makeup of our fracturing (frac) fluids via FracFocus.org.

Governance

Our Environmental, Health, and Safety (EHS) department, led by our Vice President, EHS, provides the oversight and management of our environmental footprint, including following water‑related procedures and permit requirements. Our Completion and Production teams oversee the management of operations and associated water use. Our EHS team develops water-related procedures to enact best safety practices and manage environmental incidents while our Production team develops operational procedures regarding the movement of water. We report on environmental progress each quarter, including any material environmental violations, to the Public Policy and Corporate Responsibility (PPCR) Committee of our Board of Directors.

Water Withdrawals

We operate within the Appalachian Basin, which has an abundant supply of water with low to moderate baseline water stress when compared to other basins in the United States. We use the World Resources Institute’s Aqueduct Water Risk Atlas Oil & Gas Weighting (WRI Aqueduct) to evaluate whether the water we withdraw is from stressed areas. Based on our assessment of our 2023 water withdrawal sources using WRI Aqueduct, we determined that none of our water withdrawal sources are deemed high risk areas for water stress.

Nonetheless, we recognize that water is a precious resource and aim to effectively manage our water use. Prior to any water withdrawal, we assess the water source to determine a reasonable rate that can be extracted without harm to the current uses supported by the water source, and we obtain approval from appropriate regulatory bodies as applicable. We also track historic seasonal conditions to establish a baseline for water availability from permitted surface water sources. We alter development schedules to allow water withdrawals during seasons when more water is expected to be available. We use guidance from local government agencies to determine a reasonable flow rate for the bodies of water from which we withdraw water, specifically the Susquehanna River Basin Commission and Q7-10 method.

Within our operations, we strive to minimize the quantity of fresh water used, mindfully select water sources close to our well pads to minimize transportation, and choose sources with adequate and sustainable capacity to support our withdrawal without impact to the watershed. Regulatory agencies in Pennsylvania, West Virginia, and Ohio issue permits for water withdrawal based on the availability and quality of local supplies. We have procedures in place to comply with water permitting and reporting requirements. For example, we monitor change in stream conditions through the U.S. Geological Survey website, and we record the volume pumped and pump time for all active water withdrawals. We use this data to confirm that pumping does not exceed allowable rates or daily volume. We immediately suspend water withdrawal activities during any instance of stream flows that drop below allowable levels.

To the extent possible, we use our own or third party–produced water for our operations to minimize freshwater withdrawals. We use the following definitions in this report about water use and recycling:

| Water Withdrawn/Water Consumption | Normalized Fresh Water Withdrawn | Recycled Water |

| Water obtained from sources such as lakes, rivers, reservoirs, or municipal faucets/hydrants for use in our operations. We obtain permits for our freshwater sources and adhere to all applicable local, state, and federal guidelines. Due to the nature of natural gas extraction, virtually all water we withdraw is used immediately; therefore, we use “water withdrawal” and “water consumption” interchangeably throughout this report. | The ratio of water withdrawn (in cubic meters or m3) to barrels of oil equivalent (BOE) produced per day. | Water that is recycled for reuse in our operations. This includes flowback, drilling water, and produced water collected from drilling operations. |

We recycled 96% of our produced water in 2023, exceeding our 2023 goal by 6%.

We cooperate with state agencies to obtain permits for each water withdrawal site, which includes a full evaluation of each applicable watershed. We adhere to agency recommendations on flow rates and do not exceed the maximum daily allowance to protect the quality and quantity of each water source. We take surface water withdrawals in accordance with a state-approved water management plan to prevent withdrawal during low-flow conditions. This process also helps maintain adequate water for aquatic species and downstream users. In addition to surface water withdrawal, we obtain water from municipalities in accordance with contracts with local or regional municipal water suppliers. We oversee our contractors’ compliance with water withdrawal requirements with a daily review and approval process prior to water withdrawal.

Monitoring Impacts

To prevent impacts on water supplies that are within a few hundred feet of the surface, we closely monitor well integrity. To protect shallow aquifers, we use fresh water, soap, and air to drill the section of a well that could contain any fresh water. After drilling the freshwater section of the well, steel pipes (casings) are cemented in the borehole to protect groundwater and allow production of gas. We perform casing pressure tests and run cement bond logs as required by individual state regulations, and we send reports on these tests and logs to the applicable state agency. In 2023, we had no well integrity failures that resulted in an adverse impact on the environment.

Our well-water protection program conducts both pre- and post-drill sampling at landowners’ private water supplies. We analyze water supplies (e.g., water wells, springs, ponds, streams) for general water quality constituents and metals, dissolved gas, petroleum constituents, and, if warranted, bacteriological parameters. We also follow the Marcellus Shale Coalition’s recommendation for pre-drill water supply surveys. We conduct multiple pre-drill samplings for all water sources within 3,000 feet of the site and post-drill samplings for sources within 1,500 feet of the site based on hydrogeological conditions and other factors as necessary to protect domestic water supplies.

We maintain a database of pre- and post-drill results and submit analytical results to the property owners and relevant state environmental agencies. We examine any landowner concern brought to our attention. If we perceive an issue, we immediately conduct a thorough hydrogeologic review and coordinate with the appropriate internal and external stakeholders to address and resolve the issue.

We store both fresh and recycled water in double-wall tanks and open impoundments, where allowed. Our impaired water impoundments, located exclusively in West Virginia, are inspected weekly and have leak detection systems. We do not currently have plans to create any new impaired water impoundments. In our other operating areas, we use tanks protected by containment that meet Spill Prevention, Control, and Countermeasure best practices to store water produced during production. Containment at all unconventional sites is inspected monthly for adequacy.

Transporting Water and Avoiding Spills

To further improve water efficiency, we continue to transition away from water transportation by truck. We are working to source all fresh water for our operations from pipelines to reduce truck traffic, our carbon footprint, and air emissions. As of December 31, 2023, approximately 99% of the fresh water we consume reached our sites using pipelines, compared to approximately 95% as of December 31, 2022. The year-over-year increase in piped fresh water is a result of strategic investments made to develop and expand our water pipeline infrastructure. Additionally, we adjusted our fracturing and completions development schedule to times when local streams were anticipated to have greater flow, particularly in historically water constrained areas such as northern Pennsylvania.

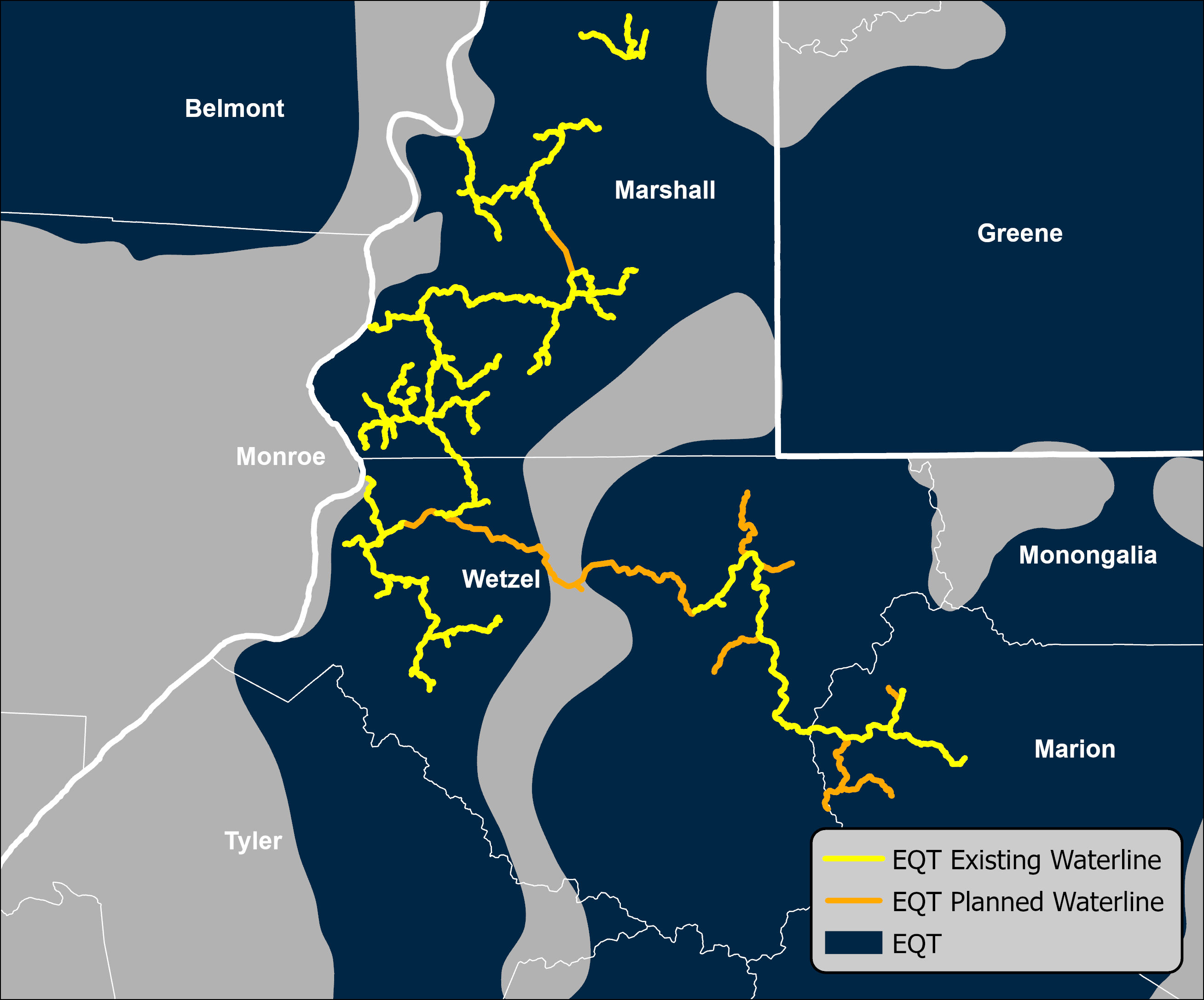

During 2023, we continued development of our 45‑mile West-Virgina mixed-use water system and added 13 miles of new pipeline to our water network. Additionally, in connection with our acquisition of Tug Hill and XcL Midstream in 2023, we acquired 60 miles of additional water pipelines, as well as two centralized water storage facilities. We use tank-level monitors to prevent spills, alarms to prevent overfilling, and technology to identify leaks in lines as soon as they occur. We require water haulers to obtain water from cellars and secondary containment before they access produced water tanks. In doing so, we aim for proactive management of our cellars and containments, which reduces the number of separate dispatches needed from water trucks to manage fluid levels. This procedure has led to a significant decrease in secondary containment compliance violations.

For 2024, we have allocated approximately $80 million of our budgeted capital expenditures to strategic water infrastructure investments, including the substantial completion of our West Virginia mixed-use water network. Ahead, we anticipate our robust portfolio of EQT-owned and operated water infrastructure will serve as the backbone for optimal development of our wells. Our water network aims to reduce environmental impacts and improve long‑term operational expenses.

EQT West Virginia Water Network

We are working to increase our operational visibility of water use in instances where water (primarily produced water) is transported via truck. Our onsite dashboards and remote water applications enable us to access real‑time data from multiple service providers and contractors in a centralized place. We have also installed global positioning systems and camera systems inside truck cabs and on trucks to provide a live view of the truck’s location. In 2023, we continued to use a scoring rubric to evaluate water haulers’ performance with a goal to balance safety, service, and cost performance. We provide our water haulers with a digitally-enabled scorecard to identify real-time scores and rankings across 14 hauler-specific performance focus areas, including speeding events and high tank issues. We regularly report scores and rankings to business partners and host open performance discussions to identify improvement opportunities. Reductions in water hauler safety events help limit the number and severity of accidents and overall impact of water hauling on local communities.

To improve our water footprint, we use the “Water App” — a logistics and data management tool — to optimize our trucking schedule, track coordination, and improve dispatch. The mapping function within the app also provides us with greater insight into our performance, which improves our overall water recycling and cost savings. In 2023, we used our current Bluetooth meter technology to compare volumes hauled by individual water trucks against the legal weight limits for the roadway areas where each truck was travelling. We compiled results and reported to contractors their percentage of overweight and underweight loads. Prevention of overweight loads protects roads and prevention of underweight loads reduces the number of water truck trips needed. Reduction of water truck trips also improves our GHG emission performance by reducing emissions associated with vehicle transportation. As a result of our efforts, our water hauling fleet's overall compliance with legal roadway weight limits improved by 10% throughout 2023.

Wastewater Management

In addition to adhering to applicable local and federal regulations, we follow best practices for safe wastewater disposal. We frequently evaluate wastewater treatment technologies with the potential to further reduce disposal amounts.

We work to recycle most of our wastewater with the collection of flowback, drilling, and produced water to reuse when fracturing new wells. We collaborate with local peers to promote sharing wastewater for reuse and have 35 active sharing agreements in place with other natural gas producers across the Appalachian Basin. These agreements generated approximately $10.7 million in cost savings in 2023 by reducing our water costs and annual transportation and disposal expenses. Over the last 3 years, we have recycled on average over 87% of the water produced from our drilling and completions operations. In 2023, we recycled 96% of our produced water.

To enhance our recycling capabilities, we use a third-party storage facility to safely store wastewater until it is ready for reuse. We do not use any wastewater for purposes other than hydraulic fracturing. We have reciprocal arrangements with other producers in Appalachia to reuse each other’s wastewater in hydraulic fracturing operations. In 2023, we recycled over 7 million barrels of our wastewater through use in other operators’ frac locations. In turn, we received over 5 million barrels of water produced by other operators for use in our operations. Overall, this resulted in over 12 million fewer billion barrels of fresh water withdrawn from the environment.

In 2023, we conducted a small-scale produced water evaporation project in Northeastern Pennsylvania. The project eliminated 320 water truck trips and saved $100,000 on a single well pad.

Any wastewater that cannot be recycled is disposed of at permitted commercial disposal facilities, and we conduct routine inspections of these facilities to confirm compliance with operating permits. Additionally, we typically employ underground injection control wells in Ohio, where geologic formations are most suitable for injection. We understand that seismic activity due to wastewater disposal can be a concern for stakeholders. Deep‑well injection represented approximately 5% of our total wastewater disposal in 2023, down from 18% in 2022. This decrease was largely the result of increased water sharing and the development and acquisition of new water pipeline networks in West Virgina. We frequently explore alternatives to injection for any wastewater we are unable to recycle. We regularly evaluate technologies that range from small-scale units designed to reduce wastewater from individual well pads to larger centralized plants.

Hydraulic Fracturing

Natural gas extraction often involves hydraulic fracturing — the process of injecting fluid into the well to create pressure to crack the underground shale formation and release the natural gas contained in the formation. The fluid injected into the well, referred to as fracturing fluid, is comprised of water mixed with sand and a small percentage of chemical additives. To reduce the potential for groundwater impacts, we complete our wells with multiple layers of steel casing and cement through a process known as triple casing, which seals and isolates freshwater zones.

We are proud to be a charter registrant of FracFocus.org, an independent website created by the Ground Water Protection Council and the Interstate Oil and Gas Compact Commission to disclose chemicals used during hydraulic fracturing. We publicly disclose, via FracFocus, all the chemicals used in our hydraulically fractured wells and regularly update such disclosures.[1]

Additionally, we continuously explore more environmentally friendly alternatives for our fluids. We do not use diesel additives[2] in our fracturing fluid and have worked to optimize and reduce the amount of other chemicals used.

[1] We do not directly claim any confidential business information (CBI) restrictions with respect to disclosing chemicals used in our hydraulically fractured wells; however, some of our chemical vendors and suppliers refuse to publicly detail the composition of their proprietary additives, citing CBI protections, and, therefore, the chemical makeup of our hydraulic fracturing fluid as reported on FracFocus may not be complete due to such third-party CBI restrictions. In the case that one or more chemicals in our hydraulic fracturing fluid cannot be publicly disclosed on FracFocus due to third-party CBI restrictions, the entry is marked as “Proprietary” in lieu of listing the chemical additive name or number. However, even if a chemical is marked as “Proprietary,” the supplier of the chemical and the chemical’s purpose and ingredient concentration is listed in the FracFocus report.

[2] Light petroleum distillates are included in our fracturing fluid. While not diesel fuel, it is in the same class of chemicals as diesel.

How We are Doing

Dashboards in our digital work environment enable us to monitor our performance against key operational indicators — including environmental incidents — and to drive internal transparency, accountability, and improved data accuracy. We have incorporated automatic notifications to alert employees when any data concerns occur, making our operations more proactive and efficient. We also use our Production Control Center to optimize schedules and to monitor our assets in real time and utilize annual third-party environmental audits for select operating facilities and sites. We have incorporated our water facilities into our digital work environment, allowing our Production Control Center to remotely monitor and control freshwater supply pipelines and produced water gathering pumps without the need for extra staff on location. We continue to add sensors to our wells to modernize our completions activities.

As shown in the table below, our primary sources of fresh water in 2023 were surface and municipal water. While many of our water storage facilities and pits passively collect rainwater for use in our operations, rainwater continues to have a minimal impact on our water usage. Our freshwater use varies annually for the following reasons:

- The location and seasonal availability of fresh water may not match the location and timing of drilling and completions activity;

- The completion of more hydraulically fractured wells results in greater total water usage; and

- The use of longer laterals — the horizontal portion of the well — requires more water for each completion on an absolute basis for each well, but reduces our overall water needs at an operator level.

Water Withdrawal/Consumption (thousands of m3)[1]

| Metric | 2021 | 2022 | 2023 |

| Freshwater sources | |||

| Surface water | 1,411 | 2,772 | 935 |

| Groundwater | <0.1 | 2 | 2 |

| Third-party water (third-party and municipal) | 4,892 | 3,058 | 5,843 |

| Total fresh water consumed[2] | 6,303 | 5,832 | 6,780 |

| Non-freshwater sources | |||

| Produced water[3] | 2,346 | 3,468 | 3,851 |

| Wastewater[4] | 149 | 277 | 795 |

| Total non–fresh water consumed | 2,495 | 3,745 | 4,646 |

| Total water consumed | 8,798 | 9,577 | 11,426 |

We do not intentionally discharge any produced water to surface water, which is why we do not disclose a strategy or standards for relevant disposal and treatment. During 2023, we did not hold any permits to discharge waste or effluent and there were no confirmed occurrences of groundwater or surface water impacts resulting from our hydraulic fracturing operations conducted in targeted formations.

Produced Water

| Metric | 2021 | 2022 | 2023 |

| Total volume of produced water[5] (thousands m3) | 3,860 | 3,504 | 4,451 |

| Amount and percent of produced water discharged to groundwater (thousands of m3) | 0 | 0 (0%) | 0 (0%) |

| Amount and percent of produced water injected (thousands of m3) | 692 | 624 (18%) | 178 (4%) |

| Amount and percent of produced water recycled[6] (thousands of m3) | 3,168 | 2,880 (82%) | 4,273 (96%) |

| Amount and percent of produced water reused at our sites[7] (thousands of m3) | 2,346 | 2,008 (57%) | 3,762 (85%) |

| Amount and percent of produced water delivered directly to third-party fracs[8] (thousands of m3) | 552 | 550 (16%) | 305 (7%) |

| Amount and percent of produced water delivered indirectly to third-party fracs via recycling facilities (thousands of m3) | 270 | 322 (9%) | 206 (4%) |

| Volume of hydrocarbons discharged to the environment via water (BOE) | 56.1 | 15 | 3 |

[1] Due to the nature of natural gas extraction, virtually all water we withdraw is used immediately; therefore, “water withdrawal” and “water consumption” are synonymous for our purposes. We do not withdraw sea water.

[2] Please note, we operate primarily within areas with very low to low Baseline Water Stress (<20%) and very low risk to Water Depletion (Water Risk Filter). Some wells operated by us within Tioga County, Pennsylvania have medium Baseline Water Stress.

[3] Includes all impaired water (produced, flowback, drilling, containment, and cellar water).

[4] Includes impaired water used from other operators and third-party recycling centers.

[5] Includes all impaired water (produced, flowback, drilling, containment and cellar water, impoundment water). Includes volumes gathered via pipeline.

[6] This is the amount of EQT-produced water that is recycled by any means, including reused at our sites, delivered directly to third‑party fracs, delivered indirectly to third‑party fracs via recycling facilities, or evaporated and/or treated and discharged to the environment without creating additional waste streams.

[7] Amount of EQT-produced water that is reused at EQT sites only.

[8] Amount of EQT-produced water that is reused at non-EQT third-party sites.