Topic Highlights

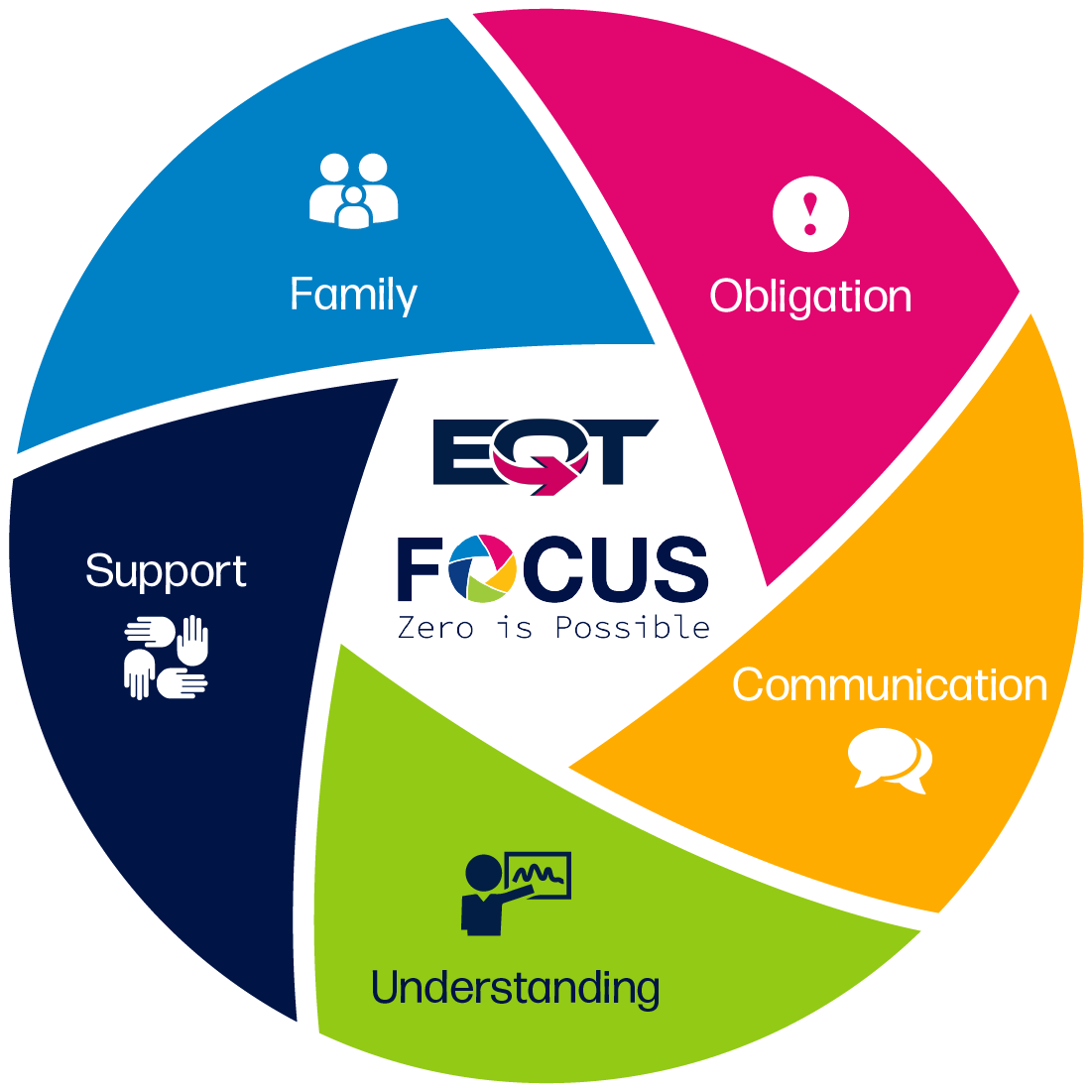

We strive to be the safest operator in the Appalachian Basin by leveraging advanced technology, comprehensive training, and clear safety guidelines. Our Family, Obligation, Communication, Understanding, and Support, or “FOCUS”, program promotes a strong overall safety culture and serves as a tool to coach our employees and contractors.

- We recorded zero employee Days Away, Restricted, or Transferred (DART) injuries.

- We reduced our employee Total Recordable Incident Rate (TRIR) by 51% compared to 2023.

- We performed 44 formal contractor audits to ensure compliance with federal, state, and EQT safe work policies.

What We Are Doing

We believe that safety is a precursor to achieving operational excellence. The safety of our employees and contract workers — and the environment in which they work — is a top priority as the nature of natural gas extraction, processing, and transportation activities, including well operations and water hauling, has the potential to pose health and safety risks to workers.

At EQT, we believe that a risk ignored is equivalent to a risk taken. Every time we ignore hazards or bypass the risk assessment process, we set ourselves up for harm. In 2024, we continued to focus our workforce on minimizing even the smallest risks, so that we can reduce the potential for incidents.

Safety Culture

As we work towards being the safest operator in the Appalachian Basin, we continue to implement technologies, comprehensive training, and clear safety guidelines so that all workers — including our large contractor base — have the resources, training, and support necessary to work safely.

We prioritize safety objectives over business objectives, and we conduct our active business operations in accordance with the applicable health and safety requirements established by the U.S. Occupational Safety and Health Administration (OSHA) and other regulatory bodies such as the Pennsylvania Department of Environmental Protection (PADEP), the Ohio Department of Natural Resources, and the West Virginia Department of Environmental Protection.

Moving beyond regulatory requirements, our FOCUS program and training promotes an overall culture of safety and serves as a coaching tool for our employees and contractors. Click on the graphic below to learn more about each component of our FOCUS program.

F is for Family

O is for Obligation

C is for Communication

U is for Understanding

S is for Support

We apply the FOCUS framework to our safety management processes, training, contractor guidance, and interaction with local communities. Our employees received the program so well that we expanded the FOCUS training to include all contractors. We regularly evaluate contractor performance and provide additional training and coaching as necessary.

The FOCUS program is a testament to our “Zero is Possible” environment, ensuring that all employees and contract workers understand why safety is important to our EQT family — at home and on the job. Employees and contractors who demonstrate exceptional commitment to our safety culture are recognized with digital challenge coins for each letter of the FOCUS acronym. Given the importance of the FOCUS program, 18 FOCUS trainings were delivered to new employees and contractors who began working with EQT following the Equitrans acquisition in July 2024. These in-person training courses worked to establish and engrain the company’s safety culture throughout the expanded workforce. Although primarily targeted at field employees, the sessions were also attended by employees from other departments, with many finding value in the training.

EQT also partnered with a third party to administer a survey focused on employees’ and contractors’ perception of our Environmental, Health, and Safety (EHS) culture in the fall of 2024. With the highest response rate since the survey’s inception in 2019, the results showed an improved safety culture perception score when compared to prior years. This feedback, alongside any incidents we have, drives the focus areas for continuous improvement. The feedback from the survey highlights areas where we can enhance our efforts, guiding our messaging and priorities for the following year. We plan to incorporate technology into our safety messages, trainings, and lessons learned to further refine our safety practices in 2025. For example, we plan to use Artificial Intelligence to aid us with safety assessments and to roll out an informative yet entertaining safety podcast.

Industry Collaboration

As a responsible corporate citizen, we seek opportunities to work with our peers to help improve overall industry safety performance. Through our active membership in the ISNetworld® (ISN) Appalachian Working Group, we share safety-related best practices and innovations with a group of natural gas producers to improve safety performance within the basin. We require all our contractors to be ISN members and to use the ISN digital platform to upload and track safety statistics, which are accessible to us for review. We also completed annual updates to our safety scorecard and processes for our contractors.

In 2024, we continued hosting roundtable discussions with nine fellow natural gas companies in our region. These meetings, which initially focused on improving safety for water haulers, evolved into broader conversations around lessons learned across our collective operational footprint — and have since been formalized into the Appalachia Safety Association (ASA). The ASA meets each quarter to share safety insights and pursue collaborative opportunities to ensure worker safety in our region.

Governance

Our Safety department works closely with the Environmental, Fleet, and Security teams. We use a centralized database to track all EHS data in one location, which is updated monthly and made available to all EQT employees. The database provides transparency across the organization regarding our overall EHS performance and the performance of individual departments.

The Vice President, EHS, who reports directly to our Chief Executive Officer, leads the Safety department. Five times a year, the Vice President, EHS provides EHS-specific updates to the Public Policy and Corporate Responsibility (PPCR) Committee of our Board of Directors (Board).

We also maintain an annual cash incentive compensation plan for our employees, known as our Short-Term Incentive Plan (STIP). The STIP is based on our successful achievement of specific financial, operational, and EHS performance measures, which are set annually by the Management Development and Compensation Committee of our Board. In 2024, EHS performance represented 20% of the annual incentive compensation opportunity under the STIP. This structure helps reinforce the importance of safety as part of our culture and provides a meaningful incentive for all employees to prioritize safety. For more information about the 2024 STIP and the related performance metrics, see our 2025 Proxy Statement.

EHS Management System and Risk Identification

Our EHS Management System is guided by the federal and state regulations set by OSHA, the PADEP, the Ohio Department of Natural Resources, and the West Virginia Department of Environmental Protection. Our EHS Management System allows us to systematically identify and manage workforce safety risks by communicating our EHS Policy, providing awareness and training, performance monitoring, and safety verification processes to our employees and contractors across all locations. Following the acquisition of Equitrans in July 2024, we reviewed and updated our EHS program to reflect the changes to our business. This included revising existing programs and adding new ones to address aspects of operations that were previously not covered. Additionally, we made strides in risk management by conducting both proactive and reactive training to better manage risks associated with our growing operations.

We conduct annual audits of our EHS Management System to provide updates when needed and ensure alignment with emerging issues and regulatory requirements. In 2024, our EHS team performed 44 audits to verify that all our contractors and employees complied with our comprehensive safety standards.

The identification, prioritization, and management of risks associated with health and safety are fundamental to our EHS Management System. Our detailed risk and hazard analysis (RHA) process uses a hierarchy of safety controls to establish and maintain safeguards. Prior to any fieldwork, the RHA requires a thorough safety review of the site construction plan and all daily onsite activities. If a task is deemed unsafe, everyone on site has the responsibility and authority to stop work without fear of retribution or discipline. To ensure the RHA operates effectively, we use a multilayered verification process, supported by a team of internal and external safety experts who oversee observation, testing, inspections, and audits. We share verification results with our leadership team, and we take immediate action to address and correct any potential weaknesses identified.

To engage our workforce in safe work decision-making, we conduct safety meetings, stand-downs, and leverage our emergency hotline. We require all employees, contractors, and vendors to report an emergency, medical issue, fire, spill, safety concern, or other issue that may occur. Our toll-free emergency hotline operates 24 hours a day, 7 days a week. Our call center received 3,735 calls in 2024 and has played a critical role in the collection of necessary information to dispatch appropriate individuals and agencies to mitigate incidents. Members of the EHS department field these calls to ensure the right teams are notified to respond.

Emergency Hotline: 1-833-990-1534

We also maintain a community hotline number for community members to report safety concerns; see Economic and Societal Impact for more information on how we protect our communities.

Safety Training

Safety training is a critical component of our workplace safety initiatives. All EQT employees receive core safety training annually, along with more frequent specialized training for employees tailored to the work performed and the types of issues faced by those employees. We customize specialized training subjects and delivery methods as needed. For example, in 2024, our monthly safety meetings with field employees, held both virtually and in-person, covered issues such as:

- Stop work authority;

- Proper use of personal protective equipment;

- Hot work;

- Lifting and rigging;

- Lockout tagout;

- Incident reporting and investigation;

- Regulatory citation information;

- Emergency preparedness;

- Outdoor safety;

- Safe driving; and

- Industry-specific technical safety training.

We continue to leverage our FOCUS training program for all employees and contractors, and we provide additional training on chemicals and chemical handling to ensure the chemicals used in our hydraulic fracturing processes are not misused. Further, new trainings that covered process safety management (PSM), U.S. Department of Transportation (DOT), and Federal Energy Regulatory Commission (FERC) topics were added in 2024 to promote the safe operation of our expanded midstream assets. During 2024, our field-based employees completed approximately 6,740 combined hours of EHS training, while our office-based employees completed approximately 2,194 combined hours of EHS training. Our contract workers completed approximately 21,378 total hours of EHS training hosted by EQT. Safety data sheets and hazard communications, including monthly safety newsletters distributed to our employees and contractors, help reinforce our trainings.

Contractor Safety

Contract workers accounted for approximately 75% of our total workforce hours in 2024 — requiring transparency from and collaboration with our partner companies. All contractors involved in drilling, construction, maintenance, or other operations must adhere to our regularly updated EHS Policies and Program, which apply to both their employees and any subcontracted workers.

Contractors must also pass a qualification process developed by ISN, which includes our contractor safety auditing procedure and requires they provide vital information on their performance in key areas including:

- Safety management systems;

- Injury and illness statistics;

- U.S. DOT inspection compliance;

- U.S. DOT motor carrier safety rating;

- Written safety programs and safety training;

- Experience modification rating; and

- Fatality history.

ISN assigns each contractor a letter grade based on the evaluation of the safety programs and performance provided by the contractor. Our EHS department collaborates with our Supplier Relations Management group to oversee contractors’ compliance with our safety standards. If a contractor does not meet our safety standards, then our EHS team works with the supplier, applicable operations departments, and Supplier Relations Management to seek improvement. As one part of these standards, contractors must maintain an ISN rating of ‘C’ or above to work on EQT sites. If the supplier does not improve, then safer service providers are engaged. Contractors who fail to meet our standards are not permitted to continue to work on our sites.

We remain engaged with our contractors as work evolves to achieve our joint commitment to safety. We track contractor safety incident rates, specifically injury and vehicle accidents, provided by contractors via ISN.

In 2024, EQT set a goal to complete 40 contractor audits. We exceeded this goal by completing 44 audits by year end. We also completed an initiative to update our EHS auditing standard operating procedure and auditing templates in 2024, which ensured both basic safety requirements and high hazard industry topics were covered during audits. Additionally, the EHS department partnered with the Information Technology (IT) team to integrate the auditing templates into our digital work environment to improve tracking and visibility of audit completion rates and results.

We have also automated certain aspects of our operations to improve efficiency and enhance workers’ safety. As the majority of the workforce at our drilling and completions operations are contractors, these enhancements have a significant impact on contractor safety. In our drilling operations, we perform remote geosteering and directional drilling services. We use satellites to remotely gather and analyze our wellbore data for quality control issues. We remotely adjust the speed and direction of drilling and, if necessary, send instructions electronically to crews on location to make corrections. This not only decreases the number of onsite personnel, thereby reducing the potential for safety issues, but it also allows us to use the best geosteerers and our business partners' best directional drillers and personnel to perform services on multiple wells and rigs simultaneously.

In our completions operations, we eliminated hammer unions — a known failure point in hydraulic fracturing operations. We replaced the labor associated with carrying and hammering hundreds of connections with a controlled, mechanically assisted rig-up, using bolted connections instead. This change reduces the risk of failed connections, improves equipment life, and creates a safer work environment with lower operational costs.

We also automated our wellhead controls to reduce the number of personnel needed on location for valve actuation. Our system increases valve reliability by automatically opening, closing, and greasing the valves on a set schedule, increasing their lifespan.

Additionally, we perform vibration analysis on our wells, which informs our pump operator if the well pump is operating within a specified “danger zone.” Avoidance of the danger zone extends the life of the pump and decreases the frequency at which pumps need to be rebuilt. To rebuild well pumps is a labor-intensive process that increases the risk of workforce injuries and environmental spills. When we reduce the number of required pump rebuilds, we improve our efficiency and our safety and minimize our environmental impact.

Road and Traffic Safety

Safe driving is an area of particular importance for us as our site activities at times require heavy truck traffic that can affect surrounding communities. Our EHS Program explicitly addresses safe vehicle operation and outlines safety expectations for both employees and contractors. Given the FOCUS program’s importance in establishing safety culture, in 2024, we provided in person FOCUS sessions to some of our larger contractors responsible for sand and water hauling. In addition to our FOCUS training, we maintain Traffic Control Plans that outline speed limits, curfews, and route restrictions for all active sites and Fleet Safety Procedures for employees, contractors, and subcontractors. We also use signage to increase awareness of traffic and/or safety concerns.

We require all employees and contractors on a location to watch a safety video and pass a test developed by our EHS department. Upon completion, workers receive a safety badge with their name, company, and vehicle information, which helps track arrivals and departures from the site. This system improves our emergency response capabilities by providing real-time information on the number of workers onsite, allowing us to provide accurate headcounts to first responders in the event of an incident.

To promote compliance with safety guidelines, all EQT work vehicles are equipped with a Geotab global positioning system (GPS) device to monitor driver behaviors. These GPS devices allow us to monitor vehicle location more easily so we can determine who was involved if we receive a community complaint or if an accident occurs. Additionally, we hire private road monitors with law enforcement backgrounds to oversee truck traffic during operations. These monitors ensure compliance with safety guidelines and investigate community complaints related to worker violations. Read more about how we work with communities to address safety concerns in Economic and Societal Impact.

We also work closely with driving safety and industry experts to reduce risks associated with operating our vehicles. Both new and experienced drivers must demonstrate their safe driving skills through a periodic supervisor observation session. New employees undergo a series of computer-based and behind-the-wheel training programs, including a defensive driving module. We provide additional instruction for employees who operate specialty vehicles or haul trailers, perform off-road travel, or drive construction vehicles on public roads. One such course is a U.S. DOT training, which enables drivers to cross state lines and remain in compliance with relevant laws. We require our drivers to recertify every 3 years. In 2024, we overhauled our driving training courses, which included five unique training courses each with multiple modules. We require contractors to record miles driven in ISN to establish a preventable vehicle accident (PVA) rate. Our contractors had a PVA rate of 2.53 in 2024, which was a slight decrease from 2023.

We require all water hauling vendor vehicles to install video cameras — one that faces the driver and another that faces the roadway. These cameras allow us to conduct periodic spot checks on the drivers to verify they follow the bonded routes, adhere to posted speed limits, and drive undistracted. Footage from these cameras also helps us determine the cause of accidents and can be used in training sessions to further enhance our safety culture.

We also continue to use our Water App, which allows us to track and monitor water trucks and other vehicles operated by our service providers to evaluate safety practices, source vehicles more efficiently, and reduce mileage. We believe this insight continually increases the effectiveness of our incident response times. For more information, see Water.

Occupational Health Services

Healthy employees are better equipped to perform their roles safely. Our industrial hygienists regularly assess the physical demands of job functions and collaborate with the EHS department to address repetitive motion hazards and potential noise exposure. We also conduct post-offer and fit for duty testing to ensure employees can safely perform their tasks. To support overall well-being, we provide all employees with free access to the Calm App for stress management. Read more about our employee wellness initiatives in Talent Attraction and Retention.

Our EHS, Human Resources (HR), and third-party medical services partners are key to maintaining employee occupational health. EHS and HR work with our third-party case management provider, Work Partners, to manage health and safety reporting. Employee health information is stored securely and is accessible only to those directly involved in the management and reporting process, per EQT’s Personally Identifiable Information Policy.

How We Are Doing

Our most important goal is to ensure our workers make it home safely. In 2024, EQT was devastated by an incident that resulted in an offsite contractor fatality. Our service provider’s employee had departed from an EQT operated location and was traveling on a rural public roadway. While navigating this public road, the vehicle veered off the roadway and over a steep embankment, ultimately resulting in the driver’s death.

After the incident, we conducted an investigation in collaboration with representatives from the impacted service provider, state police, local emergency services, and others to determine the cause of the incident. Lessons learned from this devastating incident were shared across all EQT operations.

EQT remains committed to safety for employees and contractors, with a continuing program to raise awareness of risks and the actions we can take every day to reduce them. Throughout 2025, EQT’s new program “On the Road to Zero” will continue to emphasize safety for contractors and EQT drivers.

Stop Work Authority

When a safety incident occurs, we document the event in our safety incident management database, following OSHA injury and illness recordkeeping requirements. After each incident, we conduct a thorough review to identify potential causes, explore ways to prevent recurrences, and highlight opportunities to enhance training, processes, and procedures using a hierarchy of safety controls. We use a severity chart to assign hazard points to each incident type, and each department has an annual maximum target for hazard points they can accumulate — with the aim of accumulating as few hazard points as possible. Our personnel also conduct weekly incident reviews with senior management. By tracking and analyzing safety incidents, we can assess the effectiveness of our safety management approach and work towards continuous improvement.

We monitor top indicators — including near-miss incidents, number of trainings held, audits performed on contractors and our own operations, and survey results — to identify areas for improvement. We also use several safety management verification processes to evaluate our safety program, including:

- A safety team inspection program;

- A safety team contractor monthly safety auditing program; and

- A worksite auditing program.

We analyze all results from our safety verification programs for potential systemic issues and establish actions to promote continuous and sustainable program improvement.

Work-Related Injuries[1]

| Metric | 2022 | 2023 | 2024 | |||

| Employees | # | Rate | # | Rate | # | Rate |

| Fatalities from work-related injuries | 0 | 0 | 0 | 0 | 0 | 0 |

| High-consequence work-related injuries[2] | 1 | 0.14 | 0 | 0 | 0 | 0 |

| Workforce accidents[3] | 22 | 3.00 | 17 | 2.16 | 19 | 1.51 |

| Lost-time accidents | 2 | 0.27 | 0 | 0 | 0 | 0 |

| Recordable work-related injuries (including fatalities) | 6 | 0.82 | 9 | 1.14 | 7 | 0.56 |

| Main types of work-related injuries | Majority of injuries caused by bee sting, struck by/against (aerial work platform, car door, stainless line), hand/finger injuries due to being caught in/between equipment | Majority of injuries caused by struck by/against equipment or ergonomic | Majority of injuries caused by insect sting/bites, same level fall, strain while lifting, and hand injuries due to strike by/against tools and equipment | |||

| Contractors | # | Rate | # | Rate | # | Rate |

| Fatalities from work-related injuries | 2 | 0.07 | 0 | 0 | 1 | 0.03 |

| Workforce accidents[4] | 77 | 2.88 | 94 | 3.09 | 92 | 2.52 |

| Lost-time accidents | 10 | 0.37 | 15 | 0.49 | 4 | 0.11 |

| Recordable work-related injuries (including fatalities) | 22 | 0.82 | 24 | 0.79 | 25 | 0.68 |

| Main types of work-related injuries | Majority of injuries caused by slip/trip/fall (e.g., ice, equipment), ergonomics (e.g., back injury while lifting) and heat stress | Majority of injuries caused by same level falls, caught in/between equipment, and struck by/against equipment | Majority of injuries caused by struck by/against various tools and equipment, and same level falls | |||

TRIR

| Metric | Unit of measure | 2022 | 2023 | 2024 |

| Full-time employees | Incidents per 200,000 hours worked | 0.82 | 1.14 | 0.56 |

| Contract employees | 0.82 | 0.79 | 0.68 | |

| Short-service employees | 0.14 | 0 | 0 |

DART Rate[5]

| Metric | 2022 | 2023 | 2024 |

| Employees | 0.27 | 0.13 | 0 |

Many of our employee statistics improved during 2024. For example, our employee TRIR decreased by approximately 51% compared to 2023. Although contractor work-related injuries increased by one injury in 2024, the contractor TRIR still decreased, as this rate is based on the number of hours worked during the year.

Most of our workforce injuries result from same level falls, hands or fingers caught in or between equipment, or employees being struck by or against tools and equipment. We have created videos for all employees to watch which cover prior safety incidents such as these. In the videos, the individuals who were injured describe what occurred and what could have been done differently to prevent the incident from occurring. Our field employees receive these videos very well because the message comes from their peers. Additionally, hazards such as viruses, noise, and organic compounds have the potential to cause ill health for our employees. We identified all health and safety-related hazards through testing, monitoring, and sampling.

Work-Related Ill Health[6]

| Metric | 2022 | 2023 | 2024 |

| Employees | |||

| Number of fatalities because of work-related ill health | 0 | 0 | 0 |

| Number of cases of work-related ill health | 0 | 1 | 0 |

| Contractors | |||

| Number of fatalities as a result of work-related ill health | 0 | 0 | 0 |

| Number of cases of work-related ill health | 0 | 0 | 0 |

Near Miss Frequency Rate

| Metric | 2022 | 2023 | 2024 |

| Full-time employees | 0.68 | 0.63 | 1.43 |

| Contract employees | 1.84 | 2.43 | 1.78 |

| Short-service employees | 0 | 0 | 0 |

Preventable Vehicle Accident Rate

| Metric | 2022 | 2023 | 2024 |

| Employees | 1.33 | 1.99 | 1.97 |

| Contractors | 2.56 | 2.59 | 2.53 |

Both the employee and contractor PVA rates had minor decreases in 2024 when compared to 2023. EQT remains committed to keeping safety top of mind during travel, which is shown by safe driving being the focus of our 2025 safety campaign "On the Road to Zero". We plan to focus our efforts on delivering impactful trainings, messages, and tools to improve our employee and contractor driving safety records. Areas of focus include vehicle inspections, distracted driving, journey management, and defensive driving.

[1] No workers have been excluded from our workforce health and safety data. All rates are calculated per 200,000 hours worked (# multiplied by 200,000 hours and divided by the total number of hours EQT employees or contractors worked during the applicable year).

[2] Inclusive of cases with a return-to-work date greater than six months from date of incident.

[3] Includes all reported injuries.

[4] Includes all reported injuries.

[5] DART Rate calculated as: The number of OSHA recordable injuries and illnesses that resulted in days away, restricted, or transferred multiplied by 200,000 and divided by the total number of hours EQT employees worked during the applicable year.

[6] All our employees are included in our Worker-Related Ill Health disclosures, except for workers from staffing agencies.